The construction industry is known to be one of the most polluting industries, representing a consumption of 23% of the single-use plastic waste in a city. Worldwide, it is estimated that we produce 300 metric tons of plastic annually, of which 50% is single-use plastic.ontaminants, representing a consumption of 23% of the single-use plastic waste in a city. Worldwide, we produce an estimated 300 metric tons of plastic annually, 50% of which is single-use plastic.

The impact of single use plastics is devastating, the UN says that only 9% of nine billion tons of plastic that have been produced in the world, has been recycled. Here we are not only talking about those used in large industries, but also those that are part of our daily lives, such as straws, bottles, cutlery, etc.

Many countries have joined this global agreement to reduce single-use plastic, because the reality is that if something is not done about it, by 2050 there will be more plastic than fish in the sea, as 100,000 marine animals die from plastic ingestion or entrapment every year. Scary, isn’t it?

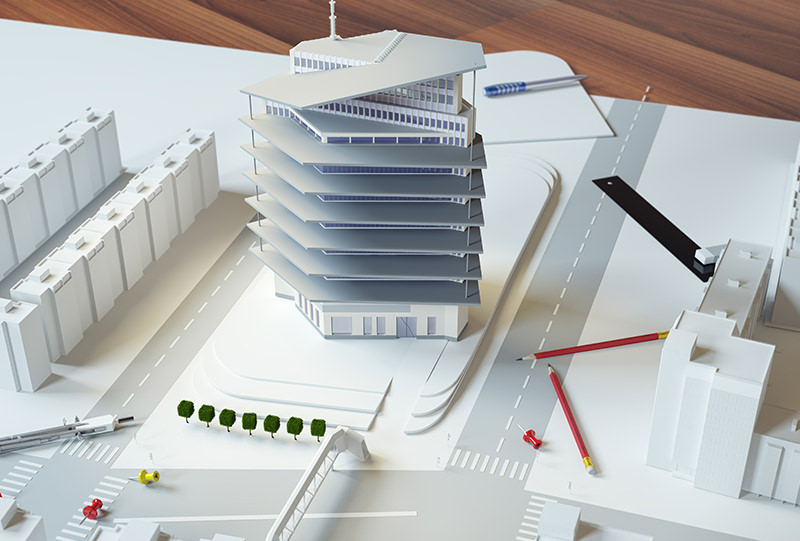

This is where we come to the question: is it possible to think about sustainable construction? The problem is big, but it has a solution: sustainable and environmentally friendly products to replace the polluting and single-use ones that mostly end up in the oceans.

With innovation, engineering and design, it is possible to set aside materials traditionally used for years, with a negative impact on the environment, to make room for others with better performance and a sustainable and profitable component.

In the case of construction, during this process many surfaces suffer irreparable damages that increase costs and time. To replace the traditional single-use plastic films used for protection, Glasst Innovation Company, a company that develops new materials with the future in mind, created Glasst Universal Protector, a liquid protector of biodegradable, oxodegradable and compostable nature that upon drying leaves a highly resistant and easily removable film.

This innovative product, which is used in several industries, avoids paint reprocessing and protects different porous and non-porous surfaces, prevents the repair of wood in closets, kitchens and floors, scratches on glass and windows and avoids damage due to slight blows, welding sparks or acid stains. Its use on construction sites complies with LEED and EDGE certification and saves up to 50% in cleaning time of concrete, paint and stucco surfaces.

It is a practical, cost-effective and sustainable solution to avoid deterioration in the finishes of parts already installed on construction sites.

Do you want to add value to your construction products and avoid cost overruns? Learn more by clicking here