Concrete formwork release agents are chemicals used in construction projects to prevent concrete from adhering to formworks: molds used in construction where concrete is poured to create structural blocks.

This protection is key to obtaining better concrete finishes visible in certain structures. In addition, they contribute to color protection as well as to the resulting concrete texture.

Among many other advantages, these products also contribute to increasing a formwork’s useful life, as they protect formwork surfaces.

However, the construction industry is not responding in time to new consumer behavior and regulations that demand more responsible products.

Most formwork release agents in the construction industry are incompatible with environmental sustainability and have low mechanical formwork performance release. In other words, they do not protect your team, the environment or your pocket.

This is why, at Glasst Innovation Company, we stand out for converting construction materials into sustainable products that guarantee work team safety, environmental protection and project sustainability.

This is why we develop innovative concrete release agents that are environmentally friendly and safe for your work team’s health. It is a very versatile product applied with a watery consistency and specialized lubricant bases that are environmentally friendly and non-toxic.

Today we want to tell you a little more about this product, explain how to choose the best reference according to your project needs and show you how to use it efficiently in your projects.

Un desmoldante ideal para cada proyecto

Glasst concrete release agents are ecological solutions to generate excellent surface finishes and extend the useful life of formworks used on construction sites. They are developed using GlasstMould ® technology, exclusively created by Glasst.

Among its many benefits are rain resistance, planet protection and people’s health, faster project cleaning times and cost-effective performance.

However, to get the most out of our product, it is also very important to understand your project’s specific needs and determine which of our references is ideal to meet them.

Get high project performance without sacrificing finish quality

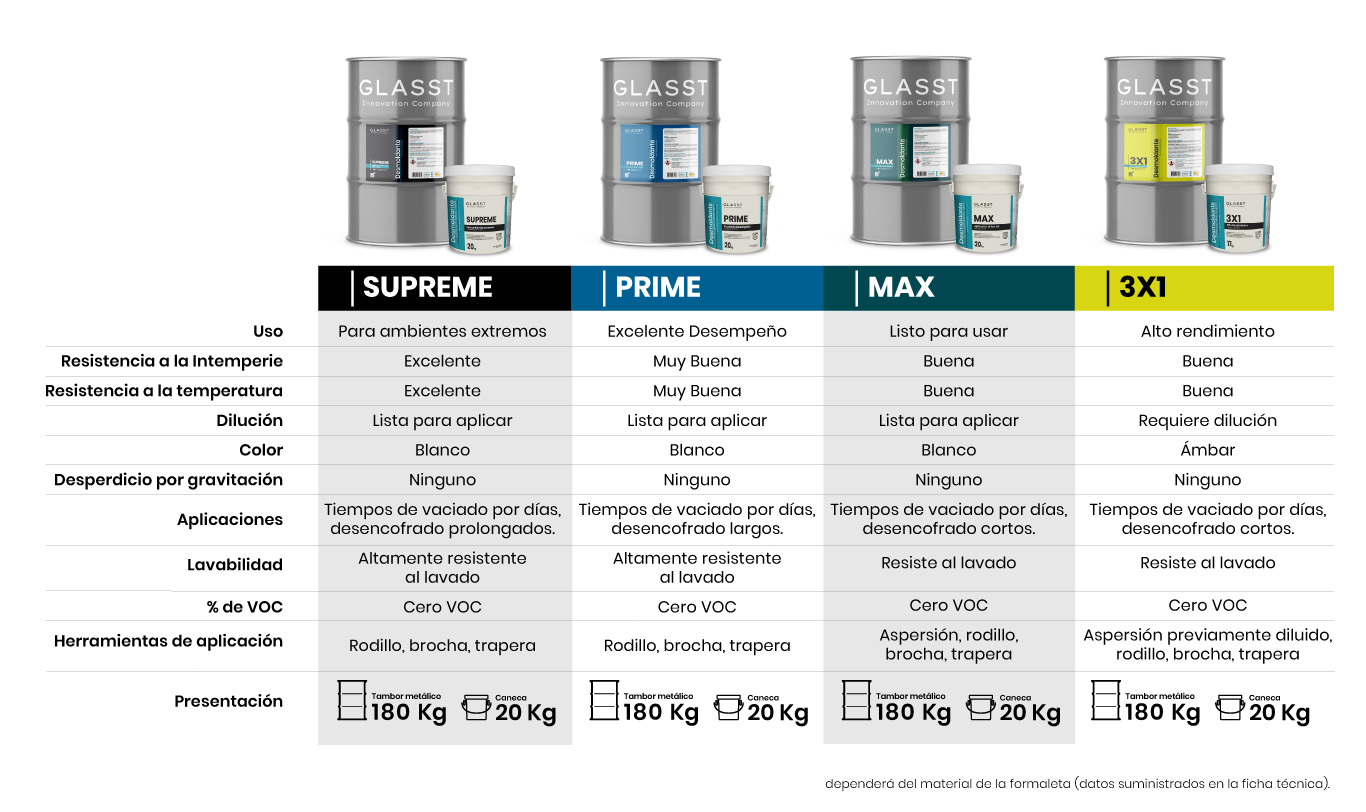

We have ideal high performance release agents for those projects that need to withstand extreme environments while guaranteeing excellent finishes.

The first is Glasst Supreme Release Agent is a product highly resistant to rainwater washout and high temperatures. This water-based release agent is used to prevent concrete from adhering to all types of formwork

It is ideal for extreme environments as a result of its high viscosity, and ideal for long pouring times.

The second-high performance reference is Glasst Prime Release Agent . This water emulsified product is chemically designed to anchor to a formwork and resist rainwater washout

It stands out for being a ready-to-use product with intermediate pour cycles and excellent performance.

Get the best cost-effective performance without sacrificing results

To achieve greater project performance, while maintaining finish and jobsite quality, we have Glasst 3X1 Release Agent.

This product is chemically designed to be anchored to the formwork and reduce gravity waste.

It stands out because it is highly concentrated and water soluble. Moreover, it has low viscosity and high performance.

All of Glasst Innovation Company‘s release agents are also different from traditional offers because they are non-toxic, environmentally friendly and safe for your team.

Furthermore, these products are easy to apply, do not affect concrete’s adhesion bridge and are rain resistant, guaranteeing quality finishes in your projects.

By using Glasst Release Agents , you also get better cost-effective performance.

Learn how to apply your release agent correctly to get the best out of your project

To know how to apply your product correctly is essential for optimal results. If you want to achieve an ideal application, you must follow product the application steps listed below correctly: Preparing the product, Adapting the formwork, Applying the release agent correctly, and Using correct application tools.

1. Preparing the product

Prime and Supreme High Performance release agents are ready to use and should not be diluted in water. Before removing the product from the original container and using it, you must stir the product.

Regarding Glasst 3X1 High Performance Release Agent, it must be diluted in water using dilution ratios of 1X1, 2X1 and up to 3X1 to achieve optimum application performance. After mixing with water, it must be shaken for five (5) minutes.

2. Preparing a Formwork

The first thing in this step is to make sure that the formworks are in good working condition that is clean, dry and without rust and concrete residues.

Next, you must remove concrete residues from the base of the formwork from previous castings, using a spatula and shavings. If necessary, you can use a polisher for optimum results.

In case a formwork is in very bad condition, the release agent can also be used to clean it before pouring concrete.

3. Applying process

To apply the product, start stirring for 5 minutes until the mixture is homogenized before using it. It can be applied using a roller, a brush or sprayers according to each release agent’s reference.

It is important to make sure to apply enough product, but not too much.

For wood formworks, apply enough product so that an additional layer of the product is left on the wood to ensure total base pore coverage

Afterwards, it is recommended to clean application tools for later use.

It is also important to protect the pallet in case of rain, even if the product is chemically designed to adhere to it. It is also important to avoid freezing the product and keep it at temperatures below 45ºC.

This product may be stored for 12 months.

4. Subsequent Finishes

Recuerda que los desmoldantes Glasst no afectan el puente de adherencia en los acabados posteriores a la aplicación. Por tal razón, con este producto innovador puedes entrar de manera temprana a finalizar la obra con la aplicación de revoques, estuco, pintura y otros.

Qualify for international sustainability certifications using our release agent, one of the best on the market

Glasst release agents are innovative products that challenge industry trends. The products’ environment and employee health friendliness sets them apart from other products on the market made from ACPM and Burnt Oils.

These materials previously mentioned are not only toxic, but they do not contribute anything to your projects’ protection. On the other hand, our release agents are perfect to contribute to your project’s economical application, while protecting block surfaces and finishes.

This minimizes costs by increasing yields per square meter and cleaning times.

Likewise, they are unique products on the market, complying with green certifications like LEED and CASA in terms of sustainability.

This is because they uses low-emission materials or materials that protect indoor air quality, giving priority to reused materials and evaluating how construction waste is handled, and they comply with the UN’s sustainable development goals.

Also, these references are produced in ICONTEC certified carbon neutral plants in Colombia. This production helps to mitigate and offset greenhouse gases going into the atmosphere in a year

Likewise, 30% of the energy used in these plants per month is generated through 3,000 solar panels installed on site and 54% of the waste generated there is used for recycling, recovery, reuse and composting.

At Glasst, we care about sustainability. We care about innovation and about doing things differently. Therefore, we continue innovating every day with products such as concrete release agents and our Universal Protector taking the best of technology to put it at the service of the planet and your projects.